Instant pvc cards making process

2009/8/16 view:

PVC sheet set for pouch laminator

Printing method: Inkjet printer (Epson series,HP series ,etc)

Laminating type: pouch laminating

Color: White ,golden or silver

Thickness: 1. Two printable PVC sheet, each one is 0.15mm

Core sheet 0.46mm

2. Two printable PVC sheet each one is 0.25mm

Core sheet 0.28mm

Size: 200x300mm or as per your requirement

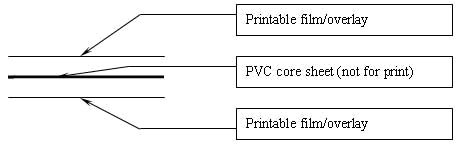

Material and laminating composition:

Detailed Composition:

1.Printable film/overlay

2.Core PVC sheet (not for print)

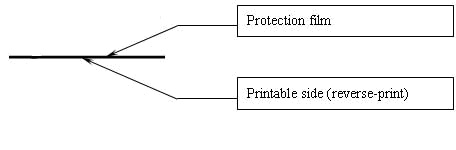

Inkjet-printing set:

Choose quality as Photo

Choose paper quality as High quality glossy photo paper

Reverse-print selected

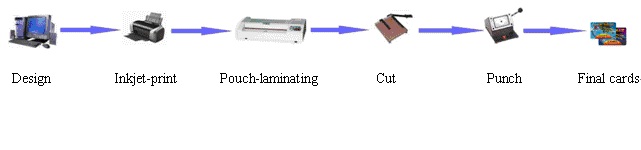

Making process example:

Steps:

1. Design in computer, you can use Corel-draw, etc. software to make design in my omputer

2. Put the blank printable overlay/film into the inkjet printer ,reverse-print (Note: when you put the printable overlay/film into the inkjet printer, please put right side for print, DON’T PUT WRONG SIDE!) you may print two films, one as front side of the card, one as backside.

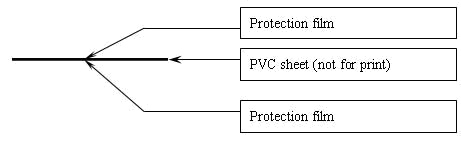

3. After printing, let the printed film dry around 5-10 minutes, then, remove the protection film from the both sides of the core PVC sheet, put one printed film on one side of the PVC sheet and put the other printed film onto the other side of the PVC sheet, then, put them all into the pouch laminator for lamination. you may set the temperature at 130-140C, to get a better laminating result,you may laminate twice.

4. After laminating, you can use a cutter to cut the laminated sheet into two half sheets (two pieces of sheet with size of 100x300mm)

5. Put the sheet into manual puncher for punching

6. After punching, you will get final cards.

- Pre:National Day Holiday from Oct 2009/9/25

- Next:New cards maker suggested proc 2009/8/16